Steel frame support system, Steel frame core tube system, Box type composite steel plate shear wall system, Multi cavity composite steel plate shear wall system.

Extruded prefabricated hollow decorative integrated exterior wall panels, Integrated exterior wall system with prefabricated lightweight insulation and veneer, Fiber cement board lightweight grouting composite wall.

Autoclaved lightweight concrete inner wall panels, Prefabricated lightweight composite energy-saving wall, Prefabricated hollow assembled interior wall system, Decorative integrated interior wall system, Floor support plate.

Prefabricated integrated decoration, Integrated wall, Thin method drainage, Integrated ground, integrated ceiling, Quick installation of water supply, Integrated package door, Integrated bathroom, Prefabricated integrated kitchen.

Longqing Southeast integrates, integrates, and optimizes advanced technological resources and achievements in the industry, and establishes in-depth cooperation with upstream and downstream enterprises through a fully open industrial cooperation platform (large construction groups, steel structure peers, design institutes, supporting manufacturers, and local governments) to jointly promote sustainable and healthy development of the industry.

We provide customers with a comprehensive enterprise that focuses on the entire prefabricated industry chain, integrating scientific research, investment, planning, design, and construction. We have successfully developed a complete set of prefabricated steel structure residential systems and have taken the lead in achieving national demonstration engineering applications.

The evaluation standards for green buildings (GB/T50378-2014), technical specifications for steel plate shear walls (JGJ/T380-2015), technical standards for prefabricated steel structure buildings (GB/T51232-2016), design standards for steel structures (GB50017-2017), evaluation standards for prefabricated buildings (GB/T51129-2017), and technical standards for steel structure residential buildings have been successively introduced, pointing out the direction for the development of prefabricated steel structure green buildings and providing theoretical basis and engineering practice guidelines.

Since 2013, the Central Committee of the Communist Party of China and the State Council have intensively issued guidance and documents on vigorously developing prefabricated steel structure buildings. President Xi Jinping made a solemn commitment to the world at the Paris Climate Summit to vigorously develop green buildings and develop prefabricated steel structure green buildings. It has become a national strategy, and the times call for the transformation and upgrading of the construction industry.

Southeast Grid has always adhered to the technological bow | leading and "high-precision and difficult" market strategic positioning. After more than 30 years of continuous development, it has become a landmark builder and green building leader. In 2013, it was approved by the National Development and Reform Commission as the only "low-carbon technology innovation and industrialization demonstration base for prefabricated steel structure residential buildings" in China, and was supported by 24 million yuan of national special funds. In 2016, it was recognized by the Ministry of Housing and Urban Rural Development as one of the first "national prefabricated building industry bases" in China. Longqing Southeast always keeps in mind the instructions of the two ministries, adheres to the responsibility of "promoting industry", fully leverages the advantages of national level technological innovation platforms, and through independent innovation and engineering practice, develops a complete set of technical systems for schools, hospitals, affordable housing, commercial housing, urban complexes, bridges, large-span spatial structures, super high-rise buildings, and industrial new cities, and actively promotes the integrated development of multiple industries such as EPC engineering general contracting and PPP investment construction and operation. By integrating, integrating, and optimizing advanced technological resources and achievements in the industry, and using a fully open industrial cooperation platform, we establish extensive and in-depth practical cooperation with upstream and downstream enterprises to jointly promote the sustainable and healthy development of the industry.

This technology has effectively solved the construction difficulties of national major scientific facilities, and has been successfully applied to major scientific facilities such as the 500 meter aperture spherical radio telescope (China Tianyan) and the 700 meter underground Jiangmen neutrino experimental detector. The research results have reached the international leading level.

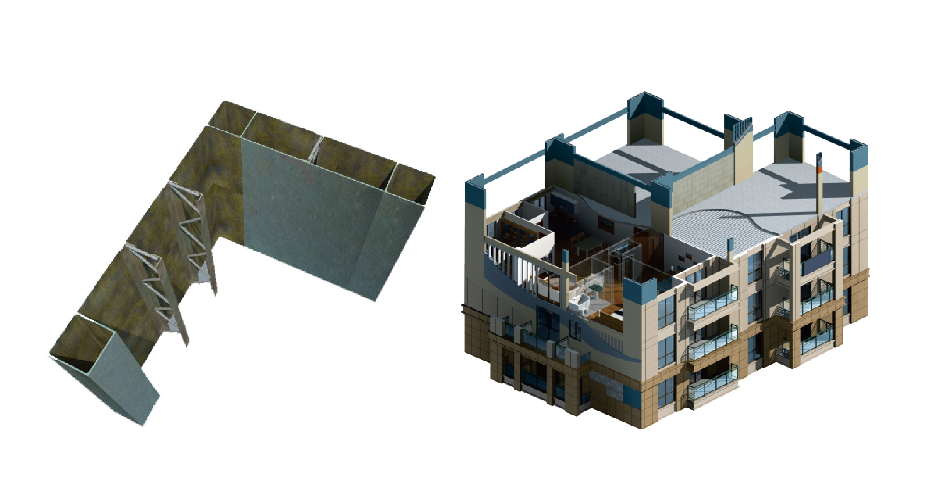

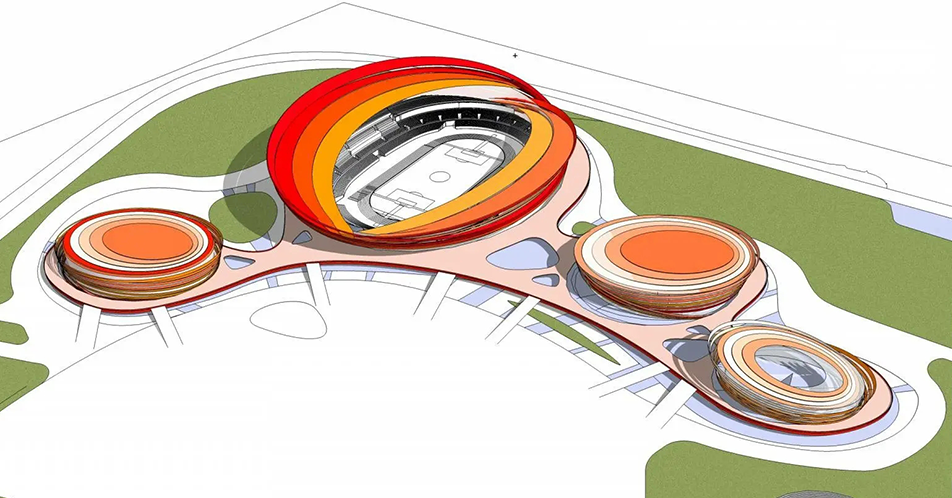

Based on the truss type multi cavity steel plate combination scissor wall structure system, integrating prefabricated floor, prefabricated wall panels, integrated decoration and other technologies, and using the SEBIM platform to achieve integrated design, factory production, and assembly construction of prefabricated steel structure buildings, it is a complete set of systematic, efficient, and advanced industrial green building solutions.

This technology effectively understands the technical difficulties of rotating and closing movable roofs on cantilever structures, and is a multidisciplinary interdisciplinary technology that integrates structure, electromechanical, and control, reaching an international leading level.

We have the full self-produced capability of Southeast accessory standards for spatial grid structures and exclusive domestic component components, achieving integrated technology from structural design, intelligent processing to on-site installation.

Based on traditional information technology in architecture, it integrates cutting-edge information technologies such as BIM, cloud computing, and mobile internet to achieve new digital management and construction.

A series of innovative metal maintenance systems with high waterproof and wind resistance have been developed from materials, board types, and structures. Through careful material selection, exquisite design, and precise construction, a high-performance and refined metal maintenance system has been formed.

By adopting intelligent equipment and digital technology, a steel structure manufacturing model with intelligent production and information management has been achieved, and zero emissions of steel structure manufacturing pollution have been achieved through process technology innovation.

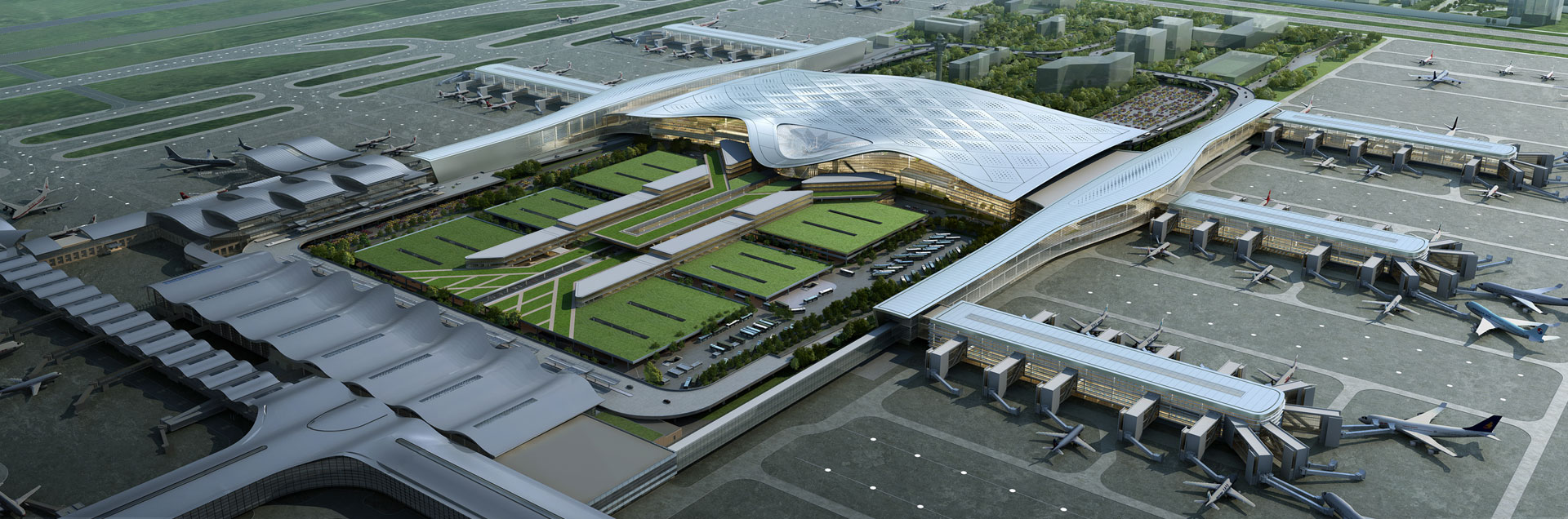

We have a complete set of comprehensive design and construction technology for large public buildings under complex construction conditions, forming a series of key steel structure construction technologies such as ultra large area, ultra large span, and irregular structure, and have always maintained a leading position domestically and internationally.

We have developed industry-leading welding technology for high-strength and thick steel plates, processing technology for complex shaped components, and collaborative construction technology based on BIM full information models. We have also innovatively developed a full process temperature, stress, deformation monitoring and compensation system to ensure construction requirements.

This technology solves a series of technical difficulties in various novel tensioning structures, including pre-stress analysis, processing and manufacturing, on-site installation, pre-stress tensioning, and construction monitoring, and is at the leading level in China.

National Aquatics Center (Water Cube)

Jinan Olympic Sports Center Swimming Pool

Olympic Badminton Artistic Gymnastics Competition Hall

Terminal 3 of Beijing Capital International Airport

Guangzhou New TV Tower

Weihai International Commodity Trading Center

Tianjin Museum

Xi'an Aircraft Industry (Group) Co., Ltd. Assembly Building 369

Sichuan Toyota Motor Co., Ltd. Joint Factory

National Aquatics Center (Water Cube)

Guangdong Science Center

Henan Art Center

China Film Museum

Henan Nanyang Yahekou Power Plant Coal Storage Project

Guangzhou International Convention and Exhibition Center

Yunnan Qujing Hall

Tianjin Metro Line 1 Project

Yantai University Multi functional Gymnasium

Shanghai Maritime University Lingang New Campus Sports Center

Weifang Olympic Sports Center Stadium

Shaanxi Famen Temple Heshi Pagoda

Hangzhou Grand Theatre

Guiyang Cigarette Factory Relocation Technology Renovation Project Joint Workshop Project

Guangzhou New TV Tower Steel Structure Project

Steel Structure Engineering of University of Electronic Science and Technology of China Gymnasium

Empty Zhonghua West Village

Shanghai Maritime University Lingang New Campus Sports Center

Wuhan Poly Culture Square Steel Structure Project

Jinan Olympic Sports Center Swimming Pool

Nanchang International Sports Center Stadium

New Steel Structure Project for Shanghai Hongqiao Station on the Beijing Shanghai High Speed Railway

Ningxia Helan Mountain Sports Stadium

National Aquatics Center (Water Cube)

Jinan Olympic Sports Center Swimming Pool

Shanghai Maritime University Lingang New Campus Sports Center

Yantai University Multi functional Gymnasium

Nanjing Jiangning Sports Center Stadium

The 8th Yunnan Provincial People's Games Zhaotong Sports Stadium

Zhejiang Huanglong Sports Center Gymnasium

T3A Main Building, Terminal 3, Beijing Capital International Airport

Qingdao Liuting Airport International Terminal

Shanghai Sheshan Forest Theater

Shanghai Maritime University Lingang New Campus Sports Center

Swimming pool and gymnasium in the resource sharing area of Songjiang University Town, Shanghai

Shanghai Crane Transport Machinery Factory Nuclear Power Complete Crane Transport Equipment Technical Renovation Project Joint Factory Building

Shanghai Pudong International Airport Expansion Project West Cargo Area Public Cargo Station

Shanghai Saikeli Automotive Mold Technology Application Co., Ltd. Phase II Factory

Shanghai Electric Lingang Heavy Equipment Base Joint Factory

Shanghai Automotive Exhibition Center

T3A Main Building, Terminal 3, Beijing Capital International Airport

Tianjin Binhai Airport renovation and expansion

Empty Zhonghua West Village

Tonglu Fuchunjiang Lijun Hotel

Hangzhou Wanyin International Building

Nanchang International Sports Center Stadium

Chengdu Shuangliu Sports Center

Guangzhou Nansha Sports Center

Weifang Olympic Sports Center Stadium

Research on Key Technologies for Manufacturing Polyhedral Space Rigid Frame Structures

New type of suspended dome steel structure project for the 2008 Olympic Badminton Gymnasium

Application and research of new seismic isolation and vibration reduction technologies at Guangdong Science Center

Fiber optic health monitoring technology research and application at Guangdong Science Center

Research and application of prestressed space pipe truss in large-span chord tube

Construction technology of bidirectional guide rail cumulative sliding method for large-span cylindrical lattice shell structure

Comprehensive technology for design and construction of large irregular single-layer mesh shell system

New bolt ball joint, point research and application